Frame selection: more than just style

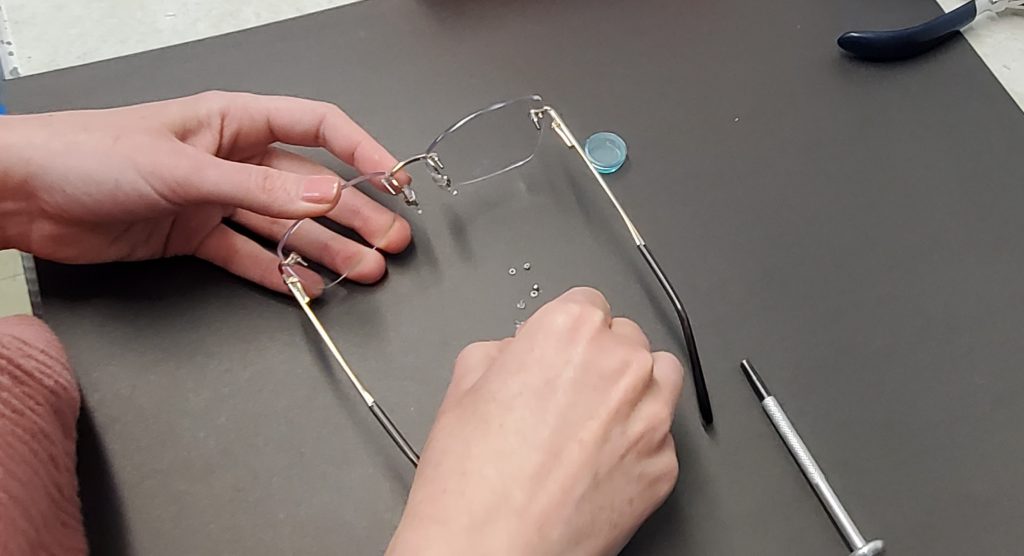

A wide range of rimless eyewear on the market makes it difficult to choose which lines to carry. Rigid frames that have zero flex at the bridge or temples can lead to loosened and cracked lenses over short periods of wear. This is because constantly unfolding and folding the temples and taking them on and off the face places stress on the areas where the chassis is attached to the lenses, transferring the flex to the lenses rather than being absorbed by the frame. Nut and bolt mountings will frequently work their way loose within a few months of regular use, and plastic compression bushings will stretch out and no longer grab the barbs of the frame. This leads to overall patient dissatisfaction with their frame choice and added work and expense for the ECP. Securing these frames with a drop of superglue is often used as a last resort but this can make the frame unusable for future lens changes–glue becomes embedded in the threaded posts or makes a mess on the lenses which is unable to be cleaned off. It also partially melts polycarbonate material which will compromise the integrity of the lenses and reduce their lifespan. Compression mountings pose their own challenges–having the correctly-sized plugs on hand, plus pliers, clippers, and the dexterity to juggle three things in your hands at once.